Even though I use my own 2 ring setup, most of what is done in this how-to is applicable to a typical Shimano 3 ring crank.

Tools needed for crank removal

-Rubber mallet

-5mm Allen wrench

-Shimano fixing bolt tool.

Step 1:

Inspect the area we are going to be working on. I actually just did a full service on my bike a few days ago but since it decided to rain today my bike collected a bunch of mud in the hard to reach areas of the Anthem X frame. Since I wanted to do this writeup anyway I thought it would be a good excuse to pop the cranks off and get the mud outta there.

Step 2:

Start by using your 5mm to loosen the non-drive-side pinch bolts. You want to alternate back and forth between loosening the bolts a few times so that you are relieving the pressure equally on both sides. Loosen the bolts to relieve all of the clamping force but you don’t have to remove them completely from the crankarm.

Step 3:

Loosen the plastic fixing bolt using the Shimano fixing bolt tool and turning counter clockwise. It should only be finger tight and easy to remove. If it is stuck then you might have to bust out the Vicegrips to get a firm hold on the Shimano tool to break the plastic bolt loose. Don’t damage the bolt as it is very much needed to reassemble the crank properly.

Step 4:

There is a small plastic shim with a pin sticking out the bottom. The pin slots into a hole on the crank axle as a last resort measure to keep the non-drive-side crank arm on the axle in case everything else comes loose. It pivots up and out of the way as illustrated in the photo. You will not be able to remove the crank without popping this shim up. You won’t be able to remove it completely, just pivot the one side up.

Step 5:

Now the non-drive-side crank arm is ready to be removed from the crank axle. You can wiggle it off or give it a few taps with the rubber mallet. I always make sure my rubber mallet is clean before I use it so that it doesn’t scratch any of my parts.

You can see what the axle looks like with the arm removed. You can also see the hole that the shim pin slotted into and why we had to pop it up. As you can see mine is already clean with fresh grease on the spline because I just did this. Yours might look different i.e. dirty/dry.

You can see what the axle looks like with the arm removed. You can also see the hole that the shim pin slotted into and why we had to pop it up. As you can see mine is already clean with fresh grease on the spline because I just did this. Yours might look different i.e. dirty/dry. Step 6:

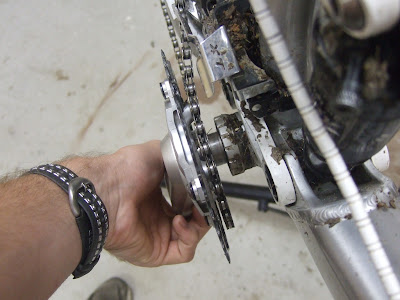

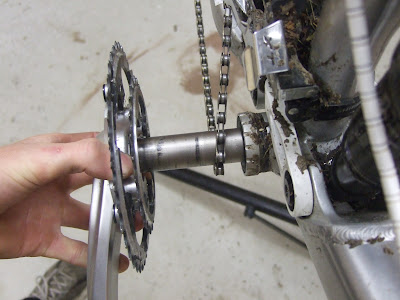

Step 6:Now you can remove the drive side crank. Begin by tapping the end of the axle with the mallet.

Grasp the crank near the chainrings and start to wiggle it out. Pop the chain off the chainring down onto the axle.

Once you have the axle almost completely pulled out of the frame you might have to give the drive-side crank arm a little mallet tap to get it the rest of the way out.

Step 7:

Inspect your mess of a BB area. Don’t panic at this point. It is pretty easy to put this all back together correctly.

Bonus Points –> How-To Remove Chainrings

*No need to remove the chainrings? Skip to Step 14

You will require a few more tools for removing the chainrings and they really depend on your crank. Some have Allen key bolts and some have Torx bolts. Mine are Torx.

Tools needed:

-Allen key or Torx bits

-Chainring nut holding tool

Step 8:

Remove the small ring first.

Step 9:

Remove the big and middle ring. They usually share the same bolt, since mine is a 2 ring setup there is only one more ring to take off instead of 2. This is where you need the nut holder. Seems a shame that such a helpful tool be given such an awful name but hey it’s a dirty job and something has gotta do it. What this tool does is holds the chainring bolt nut so that it doesn’t spin when you try to loosen the chainring bolt. Comes with 2 different ends for 2 different types of nuts.

Now you know what that slot is for on the nut, not just a huge ass flathead screwdriver ;-) Takes some co-ordination to hold the nut tool and Torx wrench at the same time. Make sure to keep your knuckles away from the chainrings cause they are sharp!

Step 10:

Keep all your bits and pieces together in an organised fashion so you don’t forget where they all go and so you don’t lose anything. Clean it all up. Use either a rag or scrub with degreaser and a toothbrush (remember to rinse with water after using degreaser).

Clean :-)

Step 11:

Now you can start to reassemble. Put the big and middle rings back on. There is an orientation arrow on my rings, on Shimano rings there is usually a bump of some kind. You need to line this bump up with the crank arm so that all of the rings work together in harmony. For most big rings there is a pin that prevents the chain from getting jammed between the ring and the crank if the chain were to shift over the top of the big ring. That pin is the alignment indicator, line it up with the crank arm. Again on the middle ring you will see the bump or protrusion of metal or carbon on the inside of the ring. Line that up with the crankarm as well.

Step 12:

Finger tighten the middle/big-ring chainring bolts. Tighten bolts that are across from each other to evenly distribute the load (as illustrated in the 2nd photo). Use a 2 stage torque sequence meaning tighten the bolts to about 5Nm or 4 out of 10 first and then finish it off by tightening them to their final 11Nm or 8 out of 10. Lots of chainring bolts are soft alloy and are quite brittle so err on the side of caution tightening them. Some blue Loctite will reduce the required tightening torque. You may (probably) also need the chainring nut holder to keep the nuts from spinning while tightening.

Tightening pattern

Tightening pattern

Step 13:

Install the small ring. In the first picture you can see I have lined up the small ring orientation arrow with the crank arm. Torque it down the same as you did the big/middle ring bolts. You can also use blue Loctite here.

Torque it down

Torque it down

*Re-install cranks

Step 14:

Clean up that hard to reach BB area of the frame. I didn’t do a world class job here, I’ll save that for your bikes ;-)

Step 15:

Your cranks are now ready to be installed onto the bike. Using some general purpose bearing grease give the two smooth/shiny parts of the axle a light coating. These areas are what contact the BB so grease will reduce noise and potential wear.

Step 16:

Flip the chain up onto the crank axle and insert the spindle into the BB shell of the bike. You might need to tap with the mallet. Don’t push the spindle in all the way until you move the chain up onto the small ring so it doesn’t get pinched between the crank and bottom bracket potentially damaging it. Once the chain is on the small ring you can push or tap the crank into the frame the rest of the way.

Tap most of the way in but be careful not to pinch the chain between the frame and the crank.

Tap most of the way in but be careful not to pinch the chain between the frame and the crank.

Lift the chain up onto the chainring.

Tap the rest of the way in

Step 17:

On the non-drive side of the bike you will see the other side of the axle protruding. Use some more bearing grease on the spline.

Install the non-drive side crankarm onto the spline and push it on with your hands as far as it will go.

Push that little plastic shim/pin back down into place as well.

Step 18:

Install the plastic fixing bolt. This bolt is and important part of the system. It controls how much load the crank applies to the bottom bracket. Not tight enough and the cranks will have play back and forth. Too tight and the bottom bracket won’t spin freely and you will blow up the bearing pretty quick. Tighten it semi-firmly like you would a headset (once you tighten the pinch bolts a little you can spin the crank and see how it feels).

Step 19:

Tighten the pinch bolts slowly rotating back and forth between the two so that they are tightened equally. Final torque spec is around 12Nm. Be careful not to round out the bolts, it is easy to do. Give them a spin to see if you have the right bearing preload. Please ignore my messy front derailleur cable in the picture ;-)