Ohhh baby we're getting down to the nitty gritty. Got home from work and just went straight to the workshop without even realising it. Made some good progress on the derailleur front. Did some experimenting with the Deore to figure out what size bolts I am going to need and what thread size/pitch. Settled with M4 x 0.7 which required pretty much the least amount of work and highest likely hood of success with the finished product. It is also a fairly standard sizing so I was able to source exactly the bolts that I was looking for.

One side gets tapped, the other enlarged

It's a pretty easy setup. The old steel pin was pushed into place and sat in a bushing which would allow the derailleur to pivot. I bored out the bushing sleeve so that it would fit snugly with the M4 bolt.

Using an old screw I had laying around I mocked it up to try the fit. Works perfect, you can also adjust the preload on the bushing by simply tightening or loosening the screw. Finished product will be purdier of course.

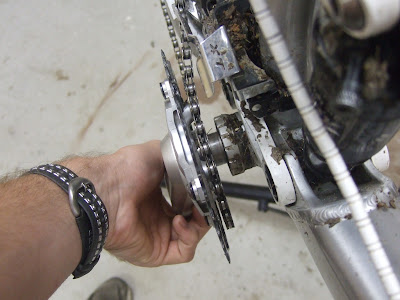

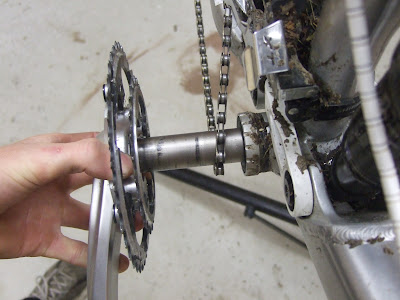

I was feeling ambitious so I moved on to drilling out the rest of the XTR Shadow pins. I also bored out and tapped the holes where the new bolts will be going in place of the pins (bored out one side, tapped the other).

This would be what you'd call a completely disassembled XTR rear derailleur.

Was feeling reeeeeaaally ambitious and polished up (wet sanded) one of the pieces and got it ready for paint prep. Progressively polished up to 2000 grit sandpaper in the areas where there will not be paint and left it at a 600 grit for the areas that are getting painted.

I also ordered the bolts that I am going to need to put it all back together. Found them on one of my new favourite websites,

http://www.tastynuts.com/ Don't ask how I found that site. They are coming from the UK however so I suspect it will be a couple weeks for them to arrive. Pretty much how long it will take me to get the derailleur ready to be re-assembled. Then there are other parts to address like retro-fitting the SAINT short cage, new pulley wheels, Ti body and cage springs, carbon hanger plate, aluminum hanger bolts................ better start making some orders soon!

Now it's time for bed.

Goodnight

Ben D

Back

Back